Comprehending the Conveniences and Innovations in the Aluminum Foundry Sector

The Aluminum Foundry industry plays a vital duty in modern production. Its light-weight buildings especially enhance fuel efficiency, especially in auto and aerospace sectors. On top of that, Aluminum's resistance to deterioration warranties long life in numerous applications. As the industry evolves, developments such as advanced recycling and additive production are improving manufacturing techniques. Exploring these advancements discloses not just the advantages however additionally the difficulties in advance for Aluminum factories in a quickly changing market.

The Lightweight Advantage of Aluminum

Aluminum's light-weight nature supplies substantial benefits across various sectors, specifically in manufacturing and transportation. Its reduced thickness enables the production of parts that are easier to handle and mount, resulting in lowered labor prices and improved efficiency. In the auto market, lighter automobiles contribute to boosted gas economic climate and lower exhausts, lining up with global sustainability objectives. In aerospace, the use of Aluminum lowers the overall weight of aircraft, which is crucial for boosting efficiency and reducing functional costs.

In addition, Aluminum's lightweight residential or commercial properties facilitate ingenious layouts that were previously impossible with heavier materials. This adaptability allows suppliers to create complicated forms and structures while preserving architectural integrity. Generally, the light-weight advantage of Aluminum not only boosts product performance however also drives advancements in modern technology and design, making it a favored product in numerous applications.

Corrosion Resistance and Longevity

The Aluminum Foundry industry is renowned for creating products with remarkable corrosion resistance, making them optimal for numerous applications. This residential property, incorporated with enhanced structural integrity, adds to the resilient efficiency advantages that Aluminum elements offer. As an outcome, sectors increasingly depend on Aluminum to satisfy demanding ecological problems without jeopardizing top quality.

Superior Deterioration Resistance

While numerous steels encounter significant difficulties from ecological variables, Aluminum stands out for its exceptional rust resistance, making it a favored option in numerous applications. This residential property is mostly as a result of an all-natural oxide layer that bases on the Aluminum surface, offering an obstacle versus dampness and destructive agents. Unlike other steels that might rust or deteriorate over time, Aluminum keeps its honesty also in extreme atmospheres, such as industrial settings or seaside locations. Furthermore, its lightweight nature combined with deterioration resistance makes it ideal for applications in aerospace, automotive, and aquatic markets. In general, Aluminum's exceptional durability not just improves product long life however also reduces maintenance expenses, presenting an engaging advantage for manufacturers and customers alike.

Improved Structural Honesty

Engineers and developers increasingly identify the significance of boosted structural honesty in contemporary applications, where both deterioration resistance and toughness are vital. Aluminum alloys, recognized for their lightweight homes, additionally exhibit phenomenal resistance to rust, making them ideal for severe settings. The innovative methods used in the Aluminum Foundry sector contribute significantly to generating components with enhanced longevity. Advanced casting processes and alloy structures are customized to fulfill particular performance needs, ensuring that frameworks can hold up against extreme conditions without jeopardizing honesty. Moreover, surface treatments and finishes boost the lifespan of Aluminum products, further alleviating damage with time. This emphasis on boosted structural honesty not just expands the usability of materials but also reduces maintenance costs, solidifying Aluminum's position as a material of choice in various industries.

Lasting Performance Advantages

Lasting performance in Aluminum components is largely attributed to their superior corrosion resistance and resilience. Unlike numerous metals, Aluminum naturally creates a safety oxide layer, which avoids rust and deterioration in various environments, consisting of industrial and aquatic settings. This fundamental property considerably expands the life-span of Aluminum products, minimizing maintenance and substitute expenses. On top of that, the light-weight nature of Aluminum improves its applicability across sectors without compromising stamina. The material's resistance to damage likewise adds to its integrity sought after applications, making it a suitable choice for automotive, aerospace, and building and construction industries. As industries significantly prioritize sustainability and durability, Aluminum's performance advantages align with modern-day engineering requirements, solidifying its duty in ingenious production processes.

Ecological Impact and Sustainability

As the Aluminum Foundry sector develops, it progressively focuses on environmental effect and sustainability, identifying the demand for accountable techniques despite climate modification. Efforts to decrease waste and power usage go to the forefront, with numerous factories taking on reusing initiatives to reclaim Aluminum scrap. This not only minimizes resources usage but likewise significantly lowers power expense, as recycled Aluminum calls for just a fraction of the energy compared to primary production.

As the Aluminum Foundry sector develops, it progressively focuses on environmental effect and sustainability, identifying the demand for accountable techniques despite climate modification. Efforts to decrease waste and power usage go to the forefront, with numerous factories taking on reusing initiatives to reclaim Aluminum scrap. This not only minimizes resources usage but likewise significantly lowers power expense, as recycled Aluminum calls for just a fraction of the energy compared to primary production.Additionally, innovations in emissions control innovations are being executed to lower air pollutants, lining up operations with stricter environmental regulations. Factories are likewise exploring alternative power resources, such as solar and wind, to power their centers sustainably. By promoting collaboration with stakeholders, the industry intends to establish ingenious services that enhance eco-friendly stewardship. Jointly, these efforts highlight a commitment to reducing the Aluminum Foundry's carbon impact while promoting a circular economy within the production market.

Advanced Manufacturing Techniques

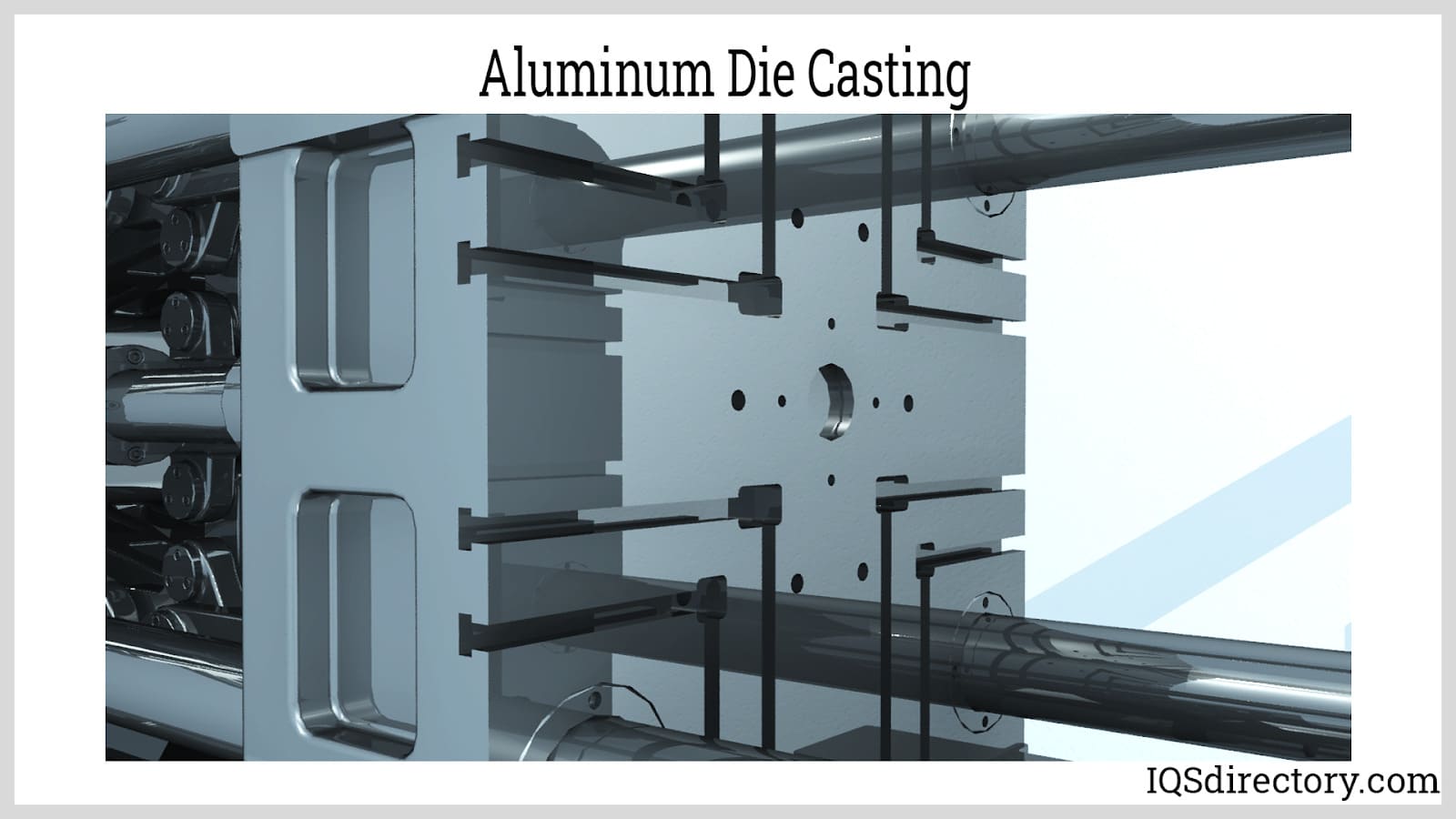

Transforming manufacturing processes, the Aluminum Foundry sector is progressively incorporating sophisticated production methods to boost effectiveness and accuracy. Techniques such as computer system numerical control (CNC) machining and additive production have arised as vital parts in enhancing production process. CNC machining allows for high-precision element manufacture, significantly lowering material waste and manufacturing time. Additive production opens brand-new methods for complex geometries and lightweight layouts that were formerly difficult to accomplish.

Transforming manufacturing processes, the Aluminum Foundry sector is progressively incorporating sophisticated production methods to boost effectiveness and accuracy. Techniques such as computer system numerical control (CNC) machining and additive production have arised as vital parts in enhancing production process. CNC machining allows for high-precision element manufacture, significantly lowering material waste and manufacturing time. Additive production opens brand-new methods for complex geometries and lightweight layouts that were formerly difficult to accomplish.In addition, the deployment of automation and robotics in Aluminum foundries enhances procedures, minimizes human error, and enhances employee safety and security. These technologies help with a more responsive manufacturing setting, making it possible for producers to adjust promptly to market needs. The integration of advanced simulation software application additionally boosts the layout and screening stages, resulting in exceptional product quality. Collectively, these methods not only enhance operational effectiveness however likewise foster advancement, placing the Aluminum Foundry sector at the center of modern-day production.

Technologies in Reusing Procedures

The Aluminum Foundry sector is not just advancing in manufacturing techniques yet is likewise making considerable strides in recycling procedures. Technologies are arising to improve the effectiveness of reusing techniques, reducing power intake and enhancing sustainability. Advanced sorting modern technologies, official website such as computerized optical sorting, allow the identification and splitting up of Aluminum from other materials with high accuracy. This results in a better of recycled Aluminum, which is vital for maintaining the honesty of the final items.

Additionally, closed-loop recycling systems are being executed, permitting makers to reuse Aluminum scrap within their own manufacturing processes. This lessens waste and promotes a circular economy. Furthermore, research into brand-new recycling techniques, such as hydrometallurgical procedures, offers the capacity for recouping Aluminum from complicated waste streams. These technologies not only add to decreasing the carbon impact of the Aluminum Foundry industry however additionally reinforce its financial viability in a significantly environmentally mindful market.

Applications Throughout Numerous Industries

Various sectors are significantly recognizing the adaptability and advantages of Aluminum Foundry products, resulting in extensive applications throughout sectors such as auto, construction, aerospace, and consumer goods. In the auto sector, Aluminum spreadings contribute to light-weight car designs, improving fuel effectiveness and efficiency. Aerospace suppliers utilize Aluminum elements for their strength-to-weight ratio, necessary for aircraft structures and components.

In building, Aluminum is preferred for its longevity and resistance to deterioration, making it optimal for home window structures, roof, and architectural assistances. Durable goods additionally profit from Aluminum Foundry products, as seen in cookware, electronics, and product packaging, where light-weight and recyclable products are vital.

The versatility of Aluminum Foundry methods enables detailed designs and exact specifications, satisfying the diverse needs of these industries. Consequently, Aluminum Foundry products are becoming integral to modern-day manufacturing procedures throughout different industries.

Future Patterns in Aluminum Foundries

As sectors remain to evolve, Aluminum shops are poised to embrace a number of key trends that guarantee to enhance efficiency and sustainability. One popular fad is the increasing adoption of digital modern technologies, consisting of automation and artificial intelligence, which enhance procedures and boost high quality control. On top of that, the press towards sustainable explanation techniques is leading shops to invest in reusing innovations, considerably reducing waste and energy intake.

Another arising fad is using sophisticated alloys and materials, satisfying the growing demand for light-weight and long lasting components throughout numerous industries (Aluminum Foundry). Additionally, the integration of additive manufacturing strategies is prepared for to revolutionize component style, using customization and lowering lead times

Another arising fad is using sophisticated alloys and materials, satisfying the growing demand for light-weight and long lasting components throughout numerous industries (Aluminum Foundry). Additionally, the integration of additive manufacturing strategies is prepared for to revolutionize component style, using customization and lowering lead timesCooperation with study institutions is also expected to drive innovation, as foundries seek to develop new processes and materials. Aluminum Foundry. Collectively, these trends indicate a transformative future for the Aluminum Foundry industry, aligning with broader goals of sustainability and efficiency

Frequently Asked Questions

What Are the Typical Costs Connected With Aluminum Foundry Production?

The typical costs related to Aluminum Foundry production consist of raw products, labor, power, devices maintenance, and overhead expenses. These factors jointly affect the general financial investment required for reliable Aluminum spreading operations.

How Does Aluminum Compare to Various Other Steels in Strength?

Aluminum, while lighter than many steels, shows remarkable strength-to-weight proportions. Compared to steel, Aluminum is much less solid but offers superb deterioration resistance, making it a positive option in applications where weight and toughness are necessary.

What Security Steps Remain In Area in Aluminum Foundries?

Security measures in Aluminum shops normally include obligatory individual protective equipment, air flow systems to manage fumes, normal devices upkeep, training programs for workers, and adherence to strict security regulations to decrease risks connected with molten steel handling.

How Is Quality Assurance Managed in Aluminum Casting Processes?

Quality assurance in Aluminum casting processes entails extensive examinations at different phases, including resources evaluation, process tracking, and end product screening. Strategies such as statistical procedure control and non-destructive screening guarantee adherence to market criteria.

What Accreditations Are Vital for Aluminum Foundry Providers?

The value of certifications for Aluminum Foundry providers consists of ISO 9001 for top why not try these out quality management, ISO 14001 for environmental monitoring, and industry-specific standards like ASTM and SAE, making sure conformity, safety, and integrity in manufacturing procedures.

The Aluminum Foundry sector plays a crucial function in modern manufacturing. The Aluminum Foundry industry is renowned for creating products with superior corrosion resistance, making them optimal for different applications. Changing manufacturing processes, the Aluminum Foundry industry is increasingly integrating sophisticated production strategies to boost performance and accuracy. The Aluminum Foundry industry is not only progressing in producing strategies yet is also making significant strides in reusing procedures. As markets continue to develop, Aluminum factories are poised to accept several essential trends that promise to enhance performance and sustainability.